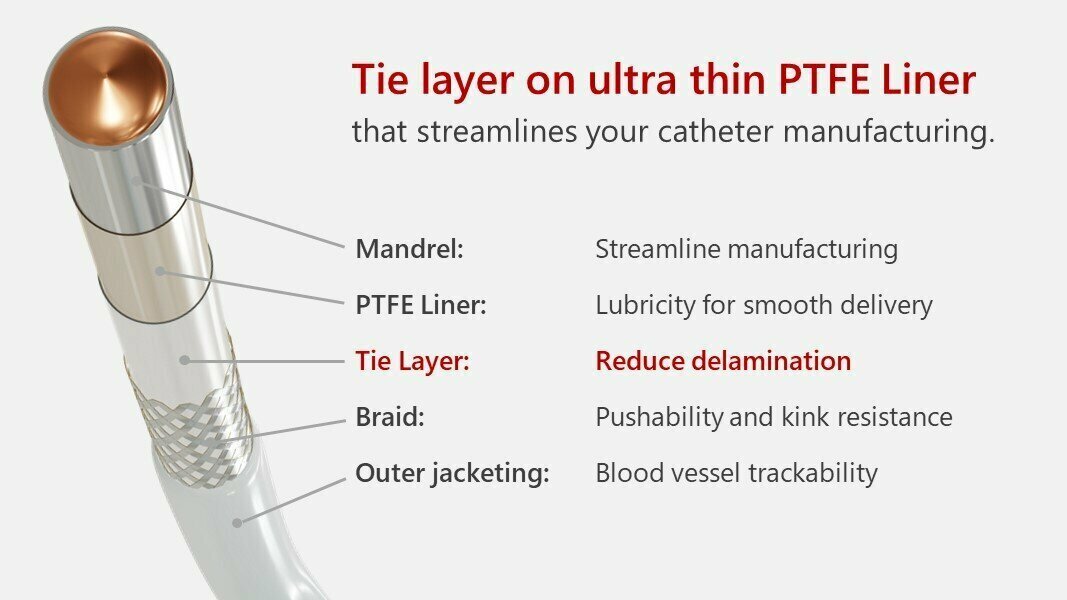

Our Tie layer coating on PTFE Liner enhances adhesion between the outer jacket and inner liner to reduce delamination. Our continuous spool to spool process on the silver-plated copper-core mandrel realizes exceptional consistency with tighter tolerance that streamlines your catheter manufacturing through the entire catheter assembly process.

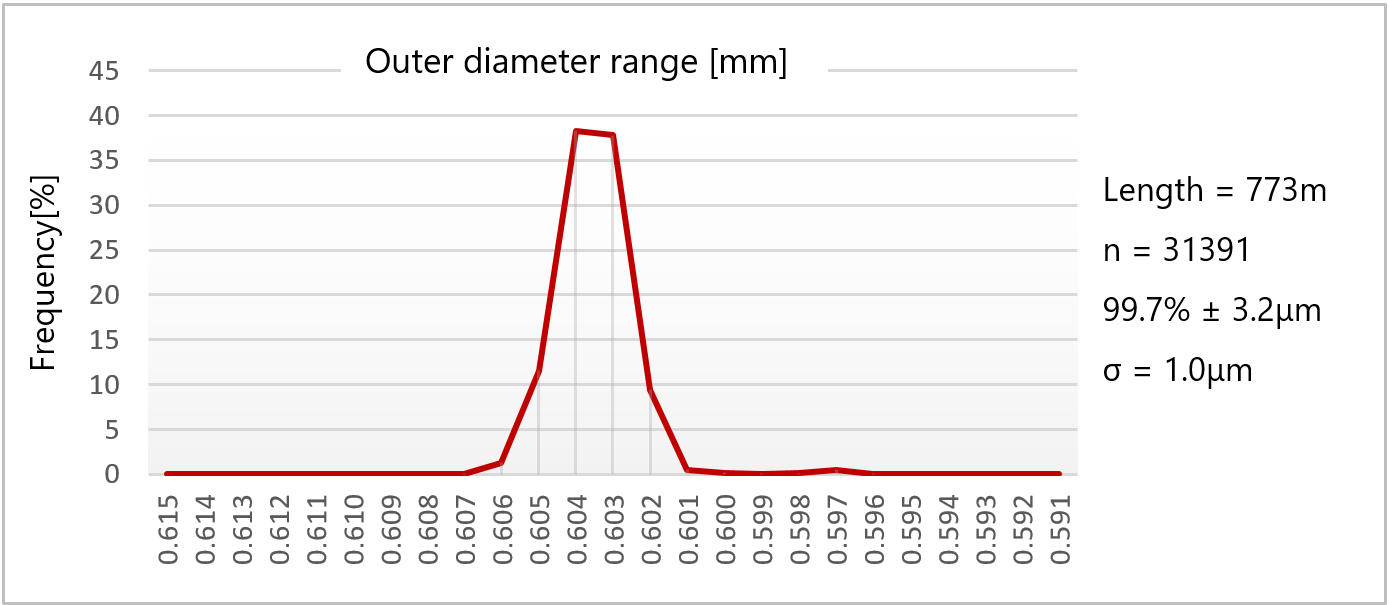

Outer Diameter Range Consistency

Our continuous spool-to-spool process realizes exceptional consistency.

99.7% is within range (± 3.2μm) with actual data of Tie layer on the PTFE Liner as below.

Specifications

- Thin wall: Min. 8μm (0.0003”)

- Wall tolerance: ±5μm (±0.0002”), depending on the material

- Inside diameter: 0.01” - 0.11” (0.3mm - 2.8mm)

- Material: Pebax®. Vestamid®, Tecothane®, Tecoflex®, Carbothane®, etc.

- Supplied: Spooled up to 1500meter, or cut length up to 2800mm (110”)

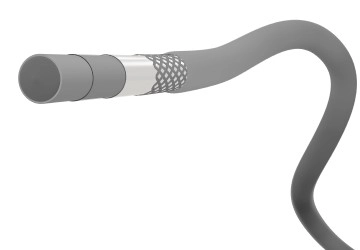

Tie Layer For Braided Shaft

- PTFE Liner features ultra thin wall, excellent lubricity, and chemical resistance, for smooth delivery.

- Braid reinforcement with material including SS304, tungsten, polymeric filaments such as 66PA, PEEK, or other materials.

- Outer jacketing is also available in a variety of materials including Nylon, polyurethane, HDPE, LDPE, or numerous other materials.