Our PTFE Liner features an ultra thin wall of 8μm (0.0003“) with tight tolerance, maximize your ID or minimize your OD with our qualified catheter liner. The continuous spooling process on the silver-plated copper-core mandrel realizes the streamlining and reduces cost significantly through the entire catheter assembly process. Ideal for the smaller catheter to enable the efficient delivery of procedures.

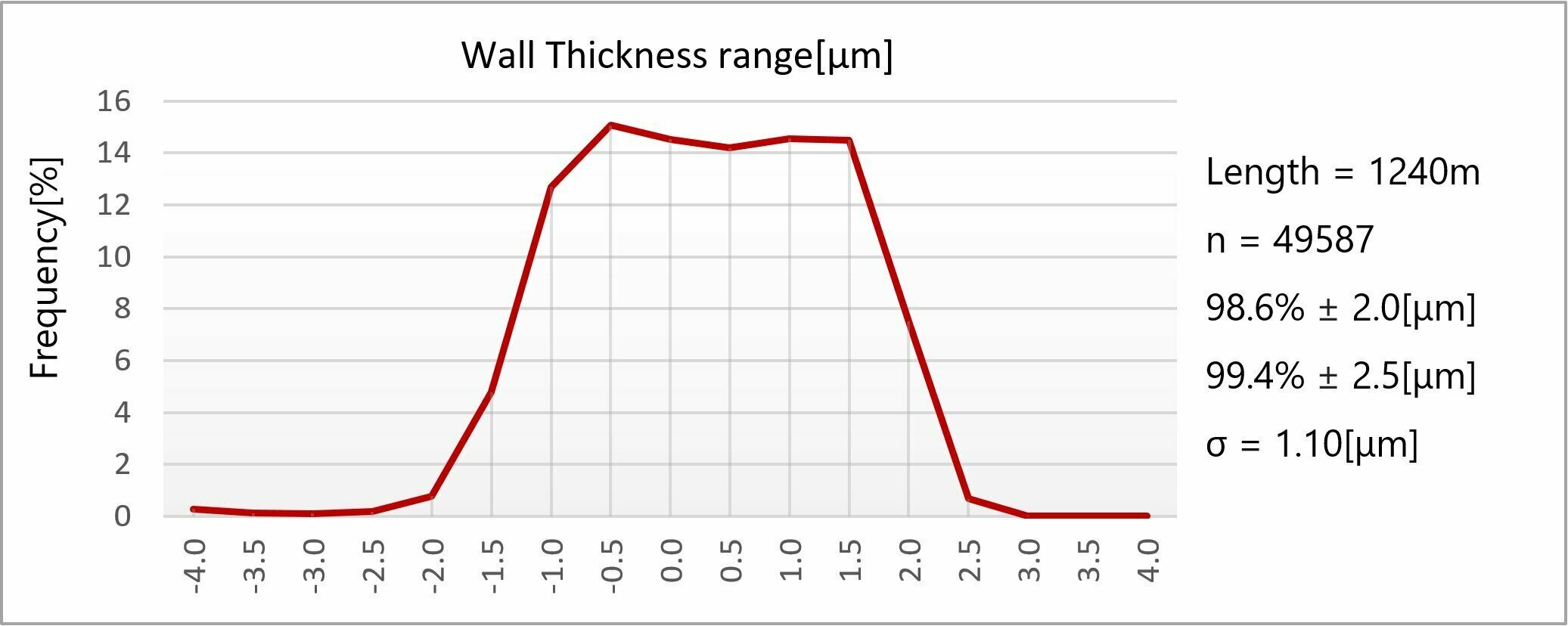

Wall Thickness Consistency

Our continuous spool-to-spool process on silver-plated copper core wire realizes exceptional consistency.

98.6% is within spec range (± 2μm) with actual measurement data of a PTFE Liner as below.

Specifications

- Ultra thin wall: 8μm - 13μm (0.0003” - 0.0005”)

- Wall tolerance: ±2μm (±0.00008”)

- Inside diameter: 0.3mm - 2.8mm (0.01” - 0.11”)

- Excellent lubricity and chemical resistance.

- Supplied on spool with silver-plated copper-core mandrel (lengths up to 1500 meter)

Quality Control

- OD is monitored on the entire length

- Pinhole check on the entire length (Marking at the pinhole)

Options

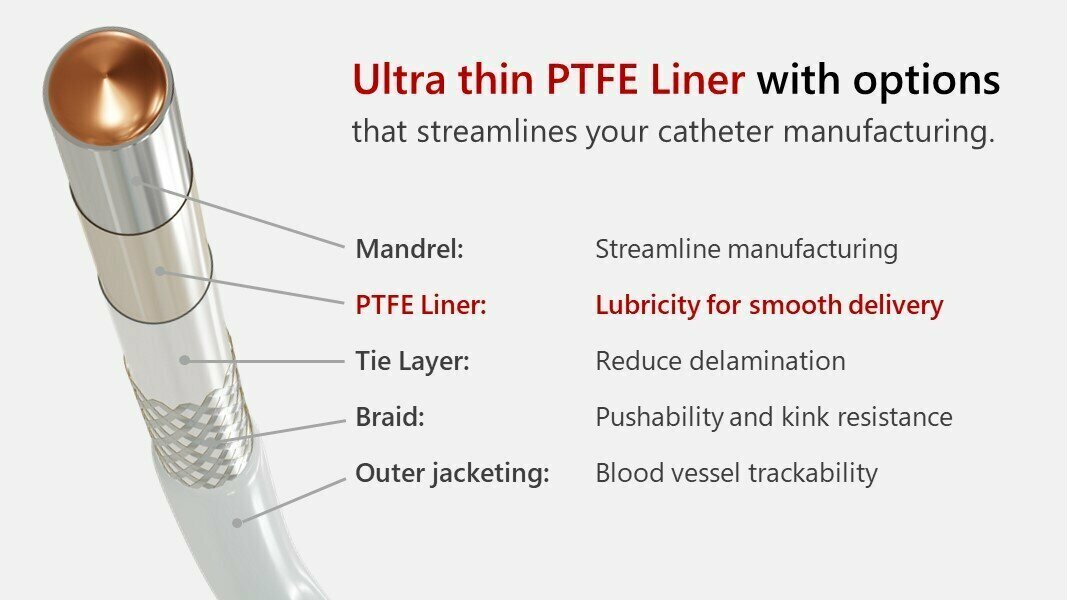

We can supply PTFE Liner with etched or Tie layer, other options are available to streamline your manufacturing.

- Thin thermoplastic Tie layer (8μm) or etched to enhance adhesion. Option of cut lengths or spooled lengths is available.

- Braid reinforcement with material including SS304, tungsten, polymeric filaments such as 66PA, PEEK, or other materials.

- Outer jacketing is also available in a variety of materials including Nylon, polyurethane, HDPE, LDPE, or numerous other materials.