Eyelets, threaded screws, or balls may be crimped, laser welded, soldered, pressed, caulked, or swaged onto the ends of stainless steel cables to optimize mechanical performance and comply with space requirements. Asahi Intecc engineers carefully review both initial tension and initial cable elongation, and wire rope elongation after bending several cycles as well as the break load to help clients select the correct terminal and stainless cable configuration.

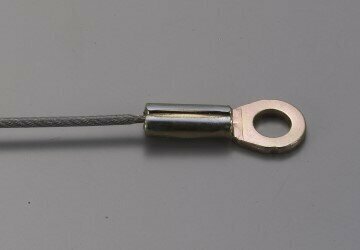

Eye End

Mainly used in connection to a pin or a screw. Wire rope stake eyes can be bent to any specified angle. Caulking is possible without removing the coating, even with coated wire rope.

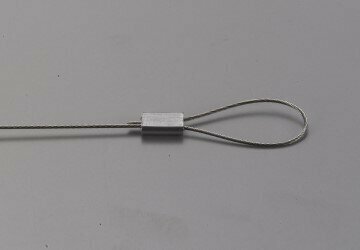

Loop End

Mainly used in connection to a pin. Used for many applications as the loop can be sized to suit specific needs.

With a thimble Used in cables with loops when wear is a concern. Provides wear resistance, greater strength, and keeps the shape of the loop open.

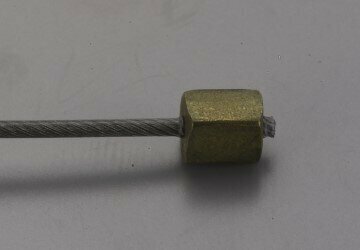

Ball End

The ball can be swaged on in either the end or the middle of an assembly. Mainly used in connection to a slit.

Threaded Studs End

Used in applications that need to make fine adjustments to the length.

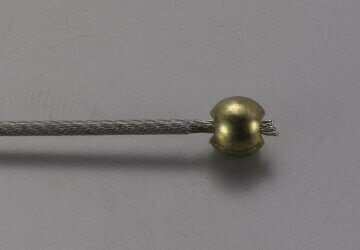

Stop End

Stop can be swaged on at either the end or the middle of an assembly. Mainly used in applications that permit rotation.